Model No

| FS1A106BV0 | FS1A206BV0 |

Port Size

| G¼ | G½ |

Flow Rate LPM

| 0.01 | 0.1 | 0.01 | 0.1 |

maximum supply pressure

10 Bar

Ambient Temperature

-10°C to +50°C

Media Temperature

+5°C to +50°C

Bowl Capacity

| 9 | 44 |

Bowl Material

Polycarbonate

installation

Vertical (as in the picture)

Materials of construction

Aluminium, Bronze, Steel, Acetal, Polycarbonate, SS, Nitrile

optional accessories

Clamp, Modular mounting kit

Note

Supply Pressure 6 bar, pressure drop Δp = 0.3bar (For Standard Models)

Application

These type of mist separators are used in Chemical, Pharmaceutical, Food processing industry, Paintshops and for other precision pneumatic systems.

- Borosilicate filtering element

- 99.99% compressed filtered air upto 0.01micron to 0.1 micron

- Suitable for Modular mounting

- Press type Manual drain for easy operation

- Separator for efficient moisture

- Mount the mist separator in line, next to a standard air filter series F1with 5 micron filter element.

- Notethe direction of flow before installation and connect piping accordingly.

- Flush pipings for dirt, dust,rust and other foreign particles.

- Install in clean atmosphere.

- Nipples of taper threads (R) to be usedwith teflon tape. Ensure Teflon tape does not enter the unit during tightening. Nipples of straight threads (G) to be used with sealing washer.

- Polycarbonate bowls may get damaged and possibly fail if exposed to synthetic oils, thinner, solvents, trichloroethylene kerosene or other aromatic hydrocarbons.

- Removes submicronic oil, water droplets and solid contaminants from compressed air.

- Used for high efficient filteration of compressed air, removing fine oil particles and droplets of sizes upto 0.01 microns

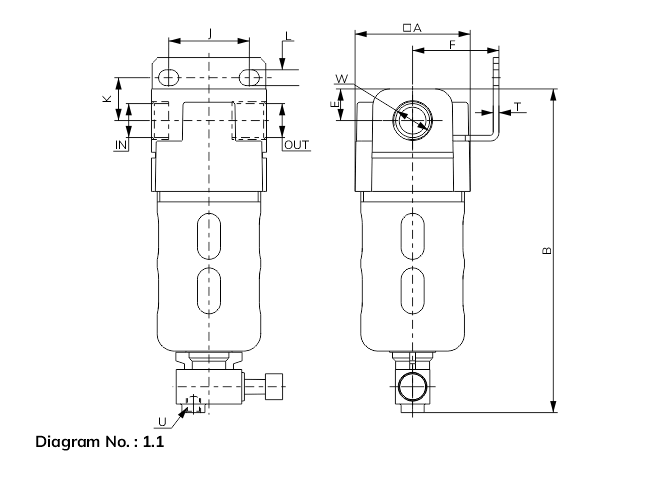

| Model No. | Diagram No. | W | A | B | E | F | J | K | L | T | U |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FS1A106BV0 | 1.1 | ¼" | 40 | 113 | 11 | 30 | 28 | 15 | 5.5 | 2 | M5 |

| FS1A206BV0 | 1.1 | ½” | 70 | 172 | 18 | 50 | 55 | 25 | 8.5 | 2 | M5 |